|

|

|

E-Z Spray Clip - On Nozzles & Riser Systems - E-Z Spray™ Nozzle Systems - Spray Patterns suitable for most spraying or misting uses in a variety of industries.E-Z Spray™ Nozzle Systems - “E-Z” Spray™ Nozzles - The Past, Present, and Future of Nozzles

- High Grade Materials Improve Life

- Reduce Maintenance Costs

- Corrosion Resistant

- Stainless Steel Clamp-On Design

|

- E-Z Installation

- Reduce Maintenance

- Flow-Rate Selection

- Low Replacement Costs

|

Minimize Downtime - No permanent damage, snap away construction pulls off, replaceable in minutes.

Applications - Spray Patterns suitable for most spraying or misting uses in a variety of industries.

- Industrial part cleaning

- Agricultural

- Irrigation

|

- Process

- Dust Control

- Fluid Agitation

|

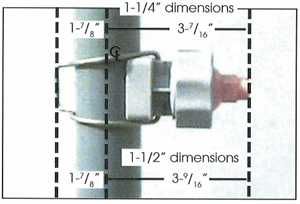

E-Z Spray™ Nozzles will fit the standard 1", 1-1/4", 1-1/2" or 2" plastic or black iron.

- Pipe in North America is manufactured to have the same standard nominal exterior diameter for a given size regardless of material or wall thickness. For instance, any 1-1/4" diameter pipe, whether plastic (CPVC or PVC) or black pipe (wrought iron) and whether schedule 40 (standard), Schedule 80 (extra heavy), or schedule 120 (double extra heavy), will have the same nominal O.D. of 1.660 inches.

- Flat Spray Nozzles - Produces a high impinging spray excellent for cleaning, rinsing, and sometimes phosphating.

- Hollow Cone Nozzles - Lower impinging spray used where the achievement of a high chemical coating weight is required on the surface of the sprayed object, as is generally the case in a zinc phosphate stage.

- Threaded Ball Nozzles - NPT female thread ends for attaching a nozzle of choice.

"E-Z" Clip-On Nozzle Assemblies - Standard clip-on nozzle assembly are listed below. To make a part number for a clip-on nozzle assembly, first select a tip, add on the Pipe Size, then the Seal Material, followed by the Spigot Size and last, if it is an O-Ring or a Flat Seal. "E-Z" Clip-On Nozzle Assemblies - Standard clip-on nozzle assembly are listed below. To make a part number for a clip-on nozzle assembly, first select a tip, add on the Pipe Size, then the Seal Material, followed by the Spigot Size and last, if it is an O-Ring or a Flat Seal.

| Pipe Size

|

Seal Material

|

Spigot Size

|

Seal Type

|

Examples:

- 125BYF8010... Describes a 1-1/4" 8010 Flat Spray Ass'y, rated at 1.0 GPM @ 40 PSI, for 1-1/4" pipe (125), with Buna-N rubber (B), a 21/32" spigot (Y) and a Flat Seal(F).

- 125VXOHC100... Describes a 1-1/4" Hollow Cone 100 nozz Ass'y, rated at 10 GPM @ 40 PSI, for 1-1/4" pipe (125), with Viton (V), a 9/16" spigot (X) and an O-Ring(O).

“E-Z” Nozzle Selection: All tips fit both Snap Risers™ and MEP “Clip-On” nozzle bodies.

| Tip Part # |

Nozzle Type |

Spray Pattern |

10 psi |

20 psi |

30 psi |

40 psi |

| ***Nozzle Capacity In Gallons Per Minute. |

| EZFS15100 |

15100 |

Flat Spray 15° |

5.0 |

7.1 |

8.5 |

10.0 |

| EZFS2560 |

2560 |

Flat Spray 25° |

3.0 |

4.2 |

5.2 |

6.0 |

| EZFS30100 |

30100 |

Flat Spray 30° |

5.0 |

7.1 |

8.5 |

10.0 |

| EZFS4050 |

4050 |

Flat Spray 40° |

2.5 |

3.5 |

5.2 |

5.0 |

| EZFS5040 |

5040 |

Flat Spray 50° |

2.0 |

2.8 |

3.5 |

4.0 |

| EZFS5050 |

5050 |

Flat Spray 50° |

2.5 |

3.5 |

4.3 |

5.0 |

| EZFS5060 |

5060 |

Flat Spray 50° |

3.0 |

4.2 |

5.2 |

6.0 |

| EZFS5070 |

5070 |

Flat Spray 50° |

3.5 |

4.9 |

6.1 |

7.0 |

| EZFS6520 |

6520 |

Flat Spray 65° |

1.0 |

1.4 |

1.7 |

2.0 |

| EZFS6530 |

6530 |

Flat Spray 65° |

1.5 |

2.1 |

2.6 |

3.0 |

| EZFS6540 |

6540 |

Flat Spray 65° |

2.0 |

2.8 |

3.5 |

4.0 |

| EZFS6550 |

6550 |

Flat Spray 65° |

2.5 |

3.5 |

4.3 |

5.0 |

| EZFS6560 |

6560 |

Flat Spray 65° |

3.0 |

4.2 |

5.2 |

6.0 |

| EZFS6570 |

6570 |

Flat Spray 65° |

3.5 |

4.9 |

6.1 |

7.0 |

| EZFS7004 |

7004 |

Flat Spray 70° |

0.2 |

0.28 |

0.35 |

0.4 |

| EZFS8010 |

8010 |

Flat Spray 80° |

0.5 |

0.71 |

0.86 |

1.0 |

| EZFS8020 |

8020 |

Flat Spray 80° |

1.0 |

1.4 |

1.7 |

2.0 |

| EZFS8030 |

8030 |

Flat Spray 80° |

1.5 |

2.1 |

2.6 |

3.0 |

| EZFS8040 |

8040 |

Flat Spray 80° |

2.0 |

2.8 |

3.5 |

4.0 |

| EZFS9560 |

9560 |

Flat Spray 95° |

3.0 |

4.2 |

5.2 |

6.0 |

| EZDT9010 |

DT9010 |

90° Deflecting |

0.5 |

0.71 |

0.86 |

1.0 |

| EZDT9020 |

DT9020 |

90° Deflecting |

1.0 |

1.4 |

1.7 |

2.0 |

| EZDT9030 |

DT9030 |

90° Deflecting |

1.5 |

2.1 |

2.6 |

3.0 |

| EZDT9040 |

DT9040 |

90° Deflecting |

2.0 |

2.8 |

3.5 |

4.0 |

| EZDT9050 |

DT9050 |

90° Deflecting |

2.5 |

3.5 |

4.3 |

5.0 |

| EZDT9060 |

DT9060 |

90° Deflecting |

3.0 |

4.2 |

5.2 |

6.0 |

| EZDT9070 |

DT9070 |

90° Deflecting |

3.5 |

4.9 |

6.1 |

7.0 |

| EZFC100 |

FC100 |

Full Cone 100 |

5.0 |

7.1 |

8.5 |

10.0 |

| EZFC60 |

FC60 |

Full Cone 60 |

3.0 |

4.2 |

5.2 |

6.0 |

| EZFC50 |

FC50 |

Full Cone 50 |

2.5 |

3.5 |

4.3 |

5.0 |

| EZFC40 |

FC40 |

Full Cone 40 |

2.0 |

2.8 |

3.5 |

4.0 |

| EZHC100 |

HC100 |

Hollow Cone 100 |

5.0 |

7.1 |

8.5 |

10.0 |

| EZHC60 |

HC60 |

Hollow Cone 60 |

3.0 |

4.2 |

5.2 |

6.0 |

| EZHC50 |

HC50 |

Hollow Cone 50 |

2.5 |

3.5 |

4.3 |

5.0 |

| EZHC40 |

HC40 |

Hollow Cone 40 |

2.0 |

2.8 |

3.5 |

4.0 |

| EZFS0000 |

0000 |

Blank Nozzle |

| EZTB125 |

TB125 |

1/8" NPT Female Threads |

| EZTB025 |

TB250 |

1/4" NPT Female Threads |

| EZTB375 |

TB375 |

3/8" NPT Female Threads |

| EZTB050 |

TB500 |

1/2" NPT Female Threads |

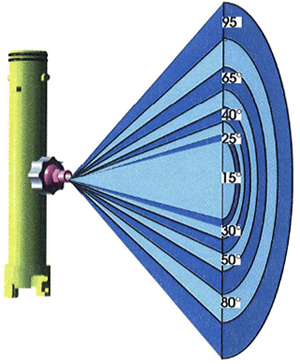

Height of Included Angle of Spray Coverage - Distance from nozzle to target in inches. Height of Included Angle of Spray Coverage - Distance from nozzle to target in inches.

| Spray Angle |

8" |

10" |

12" |

15" |

18" |

24" |

30" |

36" |

42" |

48" |

| 15° |

|

| 25° |

|

| 30° |

|

| 40° |

5.8 |

7.3 |

8.7 |

10.9 |

13.1 |

17.5 |

21.8 |

26.2 |

30.6 |

34.95 |

| 50° |

7.5 |

9.3 |

11.2 |

14 |

16.8 |

22.4 |

28 |

33.6 |

39.2 |

44.8 |

| 65° |

10.2 |

12.7 |

15.3 |

19.2 |

22.9 |

30.5 |

38.2 |

45.8 |

53.5 |

61.2 |

| 80° |

13.4 |

16.8 |

20.2 |

25.2 |

30.3 |

40.3 |

50.4 |

60.4 |

70.5 |

80.6 |

| 95° |

17.5 |

21.8 |

26.2 |

32.8 |

39.3 |

52.4 |

65.5 |

78.6 |

91.7 |

105.0 |

Bent Risers - We have the E-Z angles

- Many different angles available

- Excellent drainage

|

- Reduce cost

- One piece application for E-Z installation

|

|

|